Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec gravida, eros non iaculis sodales, lorem erat elementum dolor, eget fermentum sapien velit lobortis libero. Donec vel quam porttitor, pharetra eros pulvinar, laoreet mauris. Proin mi dui, blandit eu massa at, molestie commodo dui. Cras dictum tincidunt lorem id pretium. Cras mi ligula, ornare quis urna at, lacinia hendrerit quam.

Vivamus nec semper lacus. Donec quis imperdiet dolor. Vivamus aliquet venenatis arcu, vel rhoncus diam. Nullam malesuada tempor magna, vel iaculis eros iaculis ac. Donec dui tortor, pretium a vehicula ut, sodales non sem. Integer est est, malesuada laoreet fringilla id, porta sit amet diam. Aenean consequat imperdiet lacus non commodo. Nulla eget nisl sed urna egestas venenatis vitae nec leo. Etiam aliquet augue eget ligula consequat hendrerit. Proin placerat feugiat euismod.

Ut et justo tortor. Etiam quis sapien sit amet risus scelerisque placerat eget in eros. Morbi a tortor ac orci malesuada pellentesque. Mauris non elit est. Cras sagittis mi et diam dictum, at ullamcorper sapien posuere. In eleifend diam in elit vestibulum, a laoreet enim vulputate. Sed nec est sodales, commodo massa ut, interdum metus. Nulla facilisi. Suspendisse ultricies massa ac erat facilisis, et lobortis lacus pellentesque.

The EN 388 standard defines criteria for protection against mechanical risks, including abrasion, cut, puncture, and tear, represented by a pictogram followed by four numbers indicating performance levels.

1st Level: Abrasion resistance (0 to 4): Refers to the number of cycles required to deteriorate the sample at a constant speed.

2nd Level: Cut resistance (0 to 5): Indicates the number of cycles required to cut the sample at a constant speed.

3rd Level: Tear resistance (0 to 4): Measures the force required to tear the sample.

4th Level: Puncture resistance (0 to 4): Evaluates the force required to puncture the sample with a standardized punch.

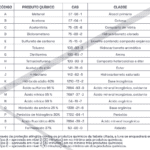

EN374-1 standard specifies the requirements for gloves to protect the user against chemical agents and/or microorganisms and defines the terms to be used. In the EN 374-1 standard, there were significant changes, such as the amendment of the permeation standard, former EN374-3, replaced by EN 16523-1:2015 and the inclusion of 6 additional chemicals, with the following table of products and letters representing them, as brought by the standard:

The EN 407 standard is an essential standard for assessing the effectiveness of gloves in protecting against thermal hazards. It defines six key parameters, including resistance to flame propagation, contact heat, convective heat, radiant heat, molten metal splash, and exposure to large quantities of molten metal. It is important to note that tests are conducted to measure the performance of gloves, not to determine absolute levels of protection.

A – Flame resistance (1 to 4): Evaluates how long the material continues to burn after the ignition source is removed.

B – Contact heat resistance (1 to 4): Indicates the temperature at which the user will not feel pain for a minimum period of 15 seconds.

C – Convective heat resistance (1 to 4): Measures how long the material delays the transfer of heat from a flame.

D – Radiant heat resistance (1 to 4): Indicates the time required for the sample to reach a certain temperature.

E – Resistance to small splashes of molten metal (1 to 4): Evaluates the time required for the sample to reach a certain temperature.

F – Resistance to large splashes of molten metal (1 to 4): Indicates the time required to cause deterioration of a material similar to skin placed behind the sample.

The EN 374-5 standard applies to all gloves designed to offer protection against microorganisms and biological agents. This standard sets requirements for resistance to penetration by bacteria and fungi, providing an effective barrier against these harmful elements. Tests are conducted to assess the gloves’ performance, ensuring user safety in environments with biological hazards.

A – Resistance to penetration by microorganisms (1 to 4): Evaluates the glove’s ability to prevent the passage of bacteria and fungi, providing effective protection for the user.

B – Liquid impermeability (passed or failed): Indicates whether the glove is capable of preventing the passage of liquids, preventing contact with harmful substances.

C – Resistance to microorganisms under pressure (passed or failed): Evaluates the glove’s ability to maintain its integrity even under pressure, ensuring continuous protection.

D – Resistance to microorganisms under vacuum (passed or failed): Assesses the glove’s ability to maintain its integrity under vacuum conditions, ensuring an effective barrier against microorganisms.

E – Resistance to blood penetration (passed or failed): Indicates whether the glove is capable of preventing blood penetration, providing additional protection in risky situations.

F – Resistance to penetration by bodily fluids (passed or failed): Evaluates the glove’s ability to prevent the passage of bodily fluids, offering complete protection to the user.

Vibration Risk: The EN ISO 10819:2013 standard sets out the minimum requirements for gloves designed to protect against mechanical vibrations transmitted to the hands at frequencies between 25 Hz and 1,250 Hz. It defines test methods to assess vibration attenuation and provides guidelines for the proper selection of gloves to protect workers from the harmful effects of vibration exposure. This standard is essential to ensure the effectiveness of vibration protection gloves and, consequently, the safety and health of workers. By adhering to the standards established by EN ISO 10819:2013, companies can mitigate the risks associated with prolonged exposure to vibration, safeguarding workers against injuries such as white finger syndrome and other vibration-related conditions.

Attenuation:

TRM = transmissibility of medium frequencies (Vibration Spectrum M: 25 to 200 Hz) ≤ 0.90 HAND VIBRAX: TRM = 0.764 (represents 23% attenuation)

TRH = transmissibility of high frequencies (Vibration Spectrum H: 200 to 1250 Hz) ≤ 0.60 HAND VIBRAX: TRH = 0.581 (represents 41% attenuation)

This Standard specifies the requirements for high visibility safety clothing, capable of visually signaling the user’s presence. High visibility clothing is intended to provide conspicuity to the wearer in any lighting condition when viewed by operators of vehicles or other mechanized equipment during daylight conditions and under headlight illumination in the dark.

We are in all states

of Brazil, including the Federal District.